ISW Corporation is a custom manufacturer of a wide range of mist eliminator units used for separating and collecting water or oil droplets from process gases and mist from smoke elimination systems. Mist eliminator systems are used in many applications:

- Petroleum refining

- Oil & gas

- Chemical

- Water treating industries

- Industrial kitchens

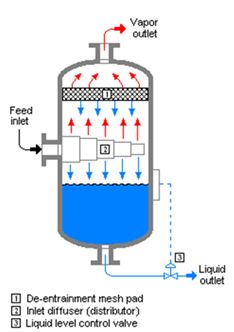

Oil or water mist in exhaust streams is typically a potential health and environmental hazard. When the mist or exhaust gas passes through the knitted wire mesh, the mist moves freely through the mesh. However, as the liquid droplets come in contact with the knitted mesh they adhere onto the surface of the wires and build into larger droplets that drop out due to gravitational forces. This process of removing toxic gases, oil mist or sulphuric acid gas has a removal efficiency up to 99%. Knitted wire mesh pads have no moving parts, can be made of high grade stainless steel and require little maintenance, therefore they are the most economical solution for mist elimination.

Specifications

Thickness: 2.0mm to 6mm

Rod Diameter: 4.0mm to 10mm

Material: Same as Knitted Wire Mesh Type

Greese Filters

ADVANTAGES

- Good separation rate (oil droplets 5 – 40 um)

- Highly efficient dehumidifying characteristic

- Low pressure losses

- High removal efficiency 98-99% attainable

- No maintenance or service required

- Easily installed in existing vessels

- Corrosion resistant properties

- Use to control air pollution

- Minimize product loss of water / oil / solvents and returns to process

APPLICATIONS

- Eliminates visible oil mist.

- Suitable for gas turbines, steam turbines and diesel engines.

- Discharges clean air to atmosphere.

- Eliminates oil stains, reduces environmental pollution – improves site conditions.