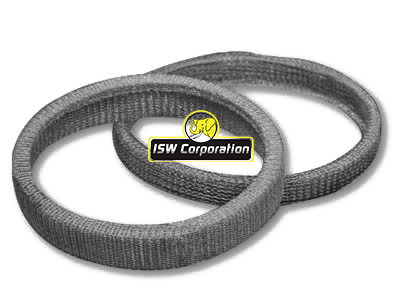

Knitted wire mesh components are formed or pressed into various shapes such as discs, cylinders, rings or squares that are widely used in automotive and industrial applications for filtration, sealing, anti-Vibration, Sound Attenuation and heat absorption. Knitted wire mesh components can virtually be produced in any size, shape, or density to enable easy assembly, riveting or spot welding, keeping costs to a minimum. Common shapes of knitted wire mesh are: ring, disc, cylindrical, rectangular, square, cube, strips, etc.

As a result of its interlocking loop construction, knitted wire mesh offers unique properties for absorbing shock and vibration. It also provides dramatically improved performance in hostile environments because of the use of stainless steel or other special alloys. Knitted wire mesh can resume 90% of its original shape because of its unique spring like structure.

Not only does knitted wire mesh provide superior performance-with an extra measure of protection against shock and vibration-but it can be fabricated from any material that can be drawn into a wire form. The most common knitted materials are stainless steel, copper, aluminum, and Inconel. Knitted wire mesh has a large surface area of wire that is excellent for absorbing sound vibrations from a highly controllable percentage of free sound deadening space. The density of the knit may also be controlled from 30 to 70%-permitting constructions of widely varying compression characteristics. When sound energy enters a knitted wire mesh element, the sound energy is absorbed into the wire structure, making the wire vibrate and converting the sound to thermal energy.

As a result of its interlocking loop construction, knitted wire mesh offers unique properties for absorbing shock and vibration. It also provides dramatically improved performance in hostile environments because of the use of stainless steel or other special alloys. Knitted wire mesh can resume 90% of its original shape because of its unique spring like structure.

Not only does knitted wire mesh provide superior performance-with an extra measure of protection against shock and vibration-but it can be fabricated from any material that can be drawn into a wire form. The most common knitted materials are stainless steel, copper, aluminum, and Inconel. Knitted wire mesh has a large surface area of wire that is excellent for absorbing sound vibrations from a highly controllable percentage of free sound deadening space. The density of the knit may also be controlled from 30 to 70%-permitting constructions of widely varying compression characteristics. When sound energy enters a knitted wire mesh element, the sound energy is absorbed into the wire structure, making the wire vibrate and converting the sound to thermal energy.

- applications

- features/advantages

- material types

- wire types

applications

- Knitted Mesh Airbag Filters

- Anti-Vibration, Sound Attenuation & Heat Shield Components

- Mesh Exhaust Decoupling Rings & Mesh Bellows Sleeves

- Knitted Wire mesh exhaust & catalytic converter seals & wraps

- Knitted Mesh Spacer Rings, Exhaust Seals & Air Gap Seals

- Diesel injector filters

- Catalytic convertor substrate

- Crimped knitted mesh wraps for catalytic convertor ceramic cores to absorb shock and vibration.

- Engine mounts for cars, trucks, marine engines, motors, and aircraft components.

- Heat shield supports, cable tray and hanger brackets.

- Anti-vibration mounts or pads for electrical panels, machinery, slabs and pipes.

- Pneumatic tool or air tool silencers

- Compressors / vacuum pumps intake air breather

- Oil-gas separation, air purification in various mechanical equipment.

features/advantages

- Offer variations of alignment, flame resistance, expansion and contraction

- High resilience to corrosive environments with excellent acid and alkali resistance

- High resilience to high and low temperatures and pressures.

- Can reduce wear and tear on piping and tubing that are exposed to vibrations.

- Can extended life to pneumatic tube carriages

- Exceptional absorption of high-energy sound due its intricate porous structure

- High strength and integral rigidity

- Good air penetrability.

- Easy to assemble and replace

- Durable and long service life

- Excellent filter precision and impedance

- Resistant to abrasion

- Can be combined with expanded metal or woven wire mesh for better filtering performance.

- Can be supplied in virtually any geometry and can be fabricated from a wide variety of alloys and plastics

- Competitively priced

- Minimal tooling costs

material types

- Stainless steel: 304, 316, 321, 310, 430, etc

- Inconel

- Copper

- Brass

- Nickel

wire types

- Flat wire compressed knitted mesh.

- Round wire compressed knitted mesh.

HOW TO ORDER

Please Specify: Bulk Rolls: Metal Alloy, Roll Width, Roll Length, Wire Diameter, Density, If Crimping Or Corrugation Is Required And Order Quantity.